THE TEXTILE INNOVATION NETWORK

Issue 1: 2021

A publication by the Technology Station: Clothing and Textiles, striving to improve the competitiveness of the South African Clothing and Textiles Sector.

I came across a few queries and interpretations regarding the term or abbreviation used in the clothing industry for what is commonly referred to as a CMT (Cut, Make and Trim) factory. Although the definition of a CMT can never be cast in stone it is important that there be some clarity especially to new entrants into the industry about what the scope of a CMT factory is in general.

According to Glock and Kunz (2000:279) “Cut make and trim contractors normally cut the garments from patterns supplied by the manufacturer and provide sewing operators, machines and thread to make garments.”

“Cut, make and trim (CMT) encompasses agreements that utilizes domestic or offshore contractors for cutting manufacturing and finishing of garments for which the product developer provides the design, patterns and fabrics”. (Keiser & Garner, 2008)

So simply put a CMT factory is a sub-contractor to a full package company or designer /design house i.e. the CMT cut’s the garment using the patterns and fabric that is supplied to them, they assemble the garment/product at the required quality level and within the agreed time frame and finishes, press and package the garment according to the specification. Trims such as zips, buttons and labels etc. have to be supplied to the CMT, however in most cases the CMT provides the thread but note you will have to bear the consequences if the quality of the thread or the colour does not meet your expectations.

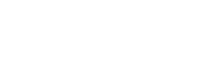

As is noted in the SMME Clothing value chain diagram figure 1, various types of subcontracting operations have emerged over the last few years viz.

- MTs: CMTs that do not have the own cutting facility i.e. they are supplied cut components by the customer firm and for want of a better term I will call them MTs (Manufacture and Trimmers). There could be various reasons for this type of relationship, but one of the most important factors is to maximize the fabric utilisation. It is estimated that fabric is constitutes about 50% of the cost of the garment and every centimetre is precious and therefore the customer wants to take control of this. It may also be that the customer had the fabric specially designed or developed by a mill and would not be comfortable finding it in the market place before they have had a chance to put it in a store.

- CUTTING SERVICE: So what if the MT does not have a cutting facility and neither the Design House/ Designer/Customer has a cutting facility? We then saw the emergence of freelance cutters that moved around from factory to factory plying their cutting skills and this eventually evolved into the establishment of dedicated Cutting Services with their own premises, staff and equipment.

- FINISHING SERVICES: This entity offered a cleaning, pressing and packaging facility and emerged mainly due to garment importers viz. wholesalers and retailers finding that landed garments were not in a state that it could be sold immediately and required cleaning off of loose threads, pressing and re-packaging the garments, and even in some cases changing the labels

Figure 1: SMME CLOTHING VALUE CHAIN (Isaacs, 2006)

TIPS FOR DESIGNERS/ RETAILERS

- The best CMTs are those that specialise in a product or at least stick to a fabric construction i.e. knitted fabrics or wovens. e.g. you cannot sew a t-shirt with a plain (lock stitch) machine, well you can but you should not. So therefore if you are making t-shirts and your CMT does not have a mock safety machine and a cover seam machine steer clear of them. Specialisation helps but is not always possible. If a CMT has only been producing one type of product for the last 5 years e.g. pants, probabilities are they are good at it and that the industry has recognized this and constantly supplies them with orders.

- The lowest price should not be the main factor when selecting a CMT. “QUALITY” and “ON-TIME” delivery should be.

- Doing small order quantities are not always good business practice for a CMTs, especially at the minimum price. If you want to produce one or two garments per style you need a dress maker or sample machinist not a CMT. Yes, there are current experimentation taking place with regard to mass customisation, but this requires a rethink on design. This however does not stop you from doing a pilot production i.e. producing a small quantity to test the water with the view of later producing a larger quantity.

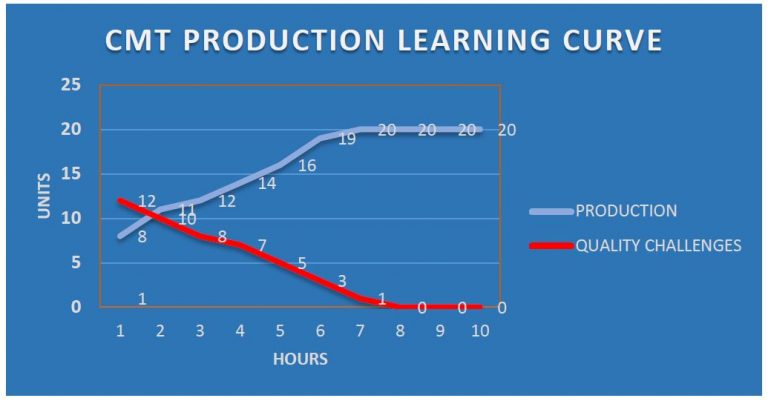

The production learning curve (figure 2) illustrates typically what may happen over a period of time as output per hour would increase as the operator familiarises themselves with the new style. Units produced increase every hour until it reaches a plateau and similarly quality challenges (repairs, re-work, rejects) decrease over time. This means that in a small order per style, the CMT would not be able to maximize its productivity (PRODUCTIVITY = OUTPUT/INPUT)

Figure 2: Production Learning curve.

TIPS FOR CMTs

- Yes, you can market your business, but you have to show what you are capable of doing e.g. prepare samples of the garments that you specialise in.

- Have an independent evaluator appraise your product, and accept constructive criticism.

- Communicate to your customer:

• List of machines available

• What services you offer

• What special skills you offer

• How many units you can produce a day/week.

• What is your claim to fame?

• Even tell the customer what you cannot do.

- Have a contactable telephone number and email address that belongs to the business.

CONCLUSION

The clothing industry has very low barriers to entry, i.e. you can start a business with one sewing machine under the arm. This however also makes it very competitive with small businesses having to fight for a piece of the pie.

What is needed is to professionalise the sector especially at the SMME level. This will be for later discussion.

Reference

Glock, R.E. & Kunz, G.I. 2000. Apparel Manufacturing, Sewn Products Analysis. New Jersey: Prentice Hall

Keiser S.J., & Garner M.B., 2008. Beyond Design, The synergy of Apparel product development. New York: Fairchild Publishing

The Textile Innovation Network a publication by the Technology Station: Clothing and Textiles, striving to improve the competitiveness of the South African Clothing and Textiles Sector.

Contact:

Technology Station: Clothing and Textiles

Cape Peninsula University of Technology

Clothing and Textile Building

Symphony Rd (off Robert Sobukwe Rd)

Bellville

t: 021 959 6826

e: techstation@cput.ac.za

w: www.tsct.co.za

fb: www.facebook.com/TSCT.CPUT